Your e-scooter won’t turn on mainly due to battery faults, wiring issues, or controller malfunctions. Battery degradation, insufficient charge, or safety lockouts often cut power. Faulty chargers, damaged ports, loose or corroded wires can interrupt current flow.

The controller or motor may have electrical or thermal failures triggering shutdowns, while moisture or rust degrade connections. Testing batteries and inspecting components helps identify the problem. Understanding these causes and troubleshooting steps reveals how to restore your scooter’s function.

Key Takeaways

- Dead or degraded battery with low voltage or capacity loss can prevent the e-scooter from powering on.

- Faulty charger, damaged charging port, or broken wiring interrupts power supply, causing startup failure.

- Controller or motor faults, including damaged components or safety shutdowns, block scooter activation.

- Corrosion, moisture intrusion, or rust on connectors and internal parts increase resistance and cause electrical failures.

- Blown fuses, tripped circuit breakers, or loose connections disrupt power flow and stop the scooter from turning on.

Common Battery Problems Affecting Power

Although e-scooter batteries typically last 2-3 years or 300-500 charge cycles, their capacity inevitably declines with age, leading to reduced range and startup failures. Proper maintenance and equipment care can reduce injury risks for both activities, and similarly, attentive battery care improves performance and longevity.

E-scooter batteries last 2-3 years but gradually lose capacity, causing shorter range and startup issues.

As batteries age, voltage drops sharply under load, causing the controller to shut down the scooter as a safety measure.

If you store the battery uncharged or rarely charge it, irreversible capacity loss can occur, preventing startup.

Monitoring battery voltage at rest and under load with a multimeter helps detect degradation; for example, a 24V system dropping below 21V under throttle indicates failure.

Over-discharging or prolonged inactivity can trigger safety circuits that block recharging. Wearing protective gear is especially vital for children under 15, amid rising scooter injuries, highlighting the importance of safety alongside proper battery management.

Regular charging and avoiding deep discharges prolong battery life, but once voltage drops excessively or capacity diminishes considerably, replacing the battery becomes necessary to restore reliable scooter power. Battery issues often stem from age-related wear or improper charging habits.

Diagnosing Charger and Charging Port Issues

When your e-scooter fails to charge, diagnosing the charger and charging port is a critical step to pinpoint the issue. Start by inspecting the charger for visible damage or frayed cables.

Test its output voltage with a multimeter or try it on another compatible device. Using a different charger with the scooter can also help confirm if the original charger is defective, as a faulty charger or cable is a common cause of charging failure.

Next, examine the charging port for burns, melting, or loose connections. Remove the port to perform continuity and voltage tests, ensuring proper charge voltage reaches the battery terminals.

| Issue Type | Diagnostic Action |

|---|---|

| Charger Failure | Test output voltage; try alternate device |

| Charger Cable Damage | Visual inspection for frays or bends |

| Port Damage | Inspect for burns, perform continuity test |

| Voltage Drop | Measure voltage at port terminals |

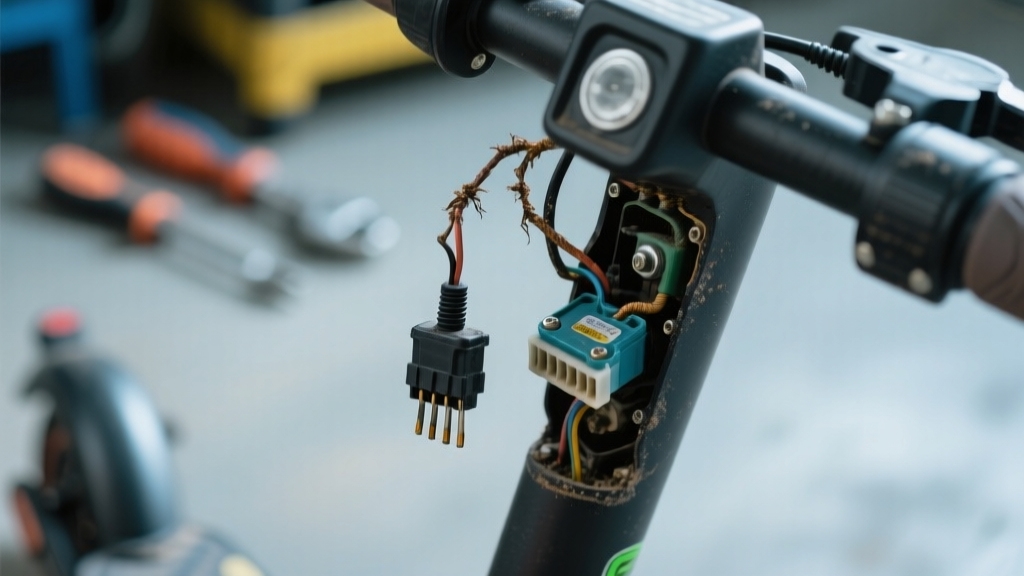

Inspecting Connections and Wiring for Faults

After verifying the charger and port functionality, the next step is to thoroughly inspect the scooter’s internal wiring and connections. Examine all wires for fraying, cuts, or exposed conductors, especially near connectors, the motor, and battery pack.

Use proper lighting and magnification to spot insulation damage or melting that suggests overloads. Gently wiggle connectors to detect loose or partially seated contacts, which are essential around the controller unit. It is also important to check battery to ensure it is fully charged and properly connected during this inspection.

Begin troubleshooting by checking all wires and connections for damage near key components like the motor and battery.

Secure any loose wires with electrical tape or replace faulty connectors where possible. Utilize a multimeter to measure voltage at battery terminals and check continuity across wiring harnesses, fuses, and circuit breakers. Inspect fuse wiring for corrosion or damage, ensuring all terminals remain secure.

Faulty wiring here can lead to power interruptions or prevent the scooter from turning on. For persistent issues, consider whether performing a reset procedure similar to electronic locks could restore functionality.

Troubleshooting Power Button and Safety Switches

If the scooter refuses to power on despite a healthy battery and intact wiring, the issue often lies with the power button or safety switches.

Start by firmly pressing and holding the power button for several seconds to rule out activation delay.

Inspect for signs of corrosion or damage on the button assembly, which may require cleaning or replacement.

Next, verify that the kickstand is fully retracted and brake levers are disengaged; these safety switches prevent power flow when activated.

Manually test each switch’s responsiveness and use a multimeter to check continuity if possible.

Also, examine related wiring for loose connectors or corrosion near the handlebar controls and kickstand. Checking connections is a primary step in diagnosis.

Re-seating connectors can restore contact, but damaged wiring should be professionally repaired to ensure reliable power engagement. Regular maintenance and timely inspection can prevent issues related to worn-out switches and wiring failures.

Controller Malfunctions and Their Impact

Beyond power buttons and safety switches, controller malfunctions often play a significant role in an e-scooter failing to turn on. You should first check for stable battery voltage and secure connections since loose, corroded, or damaged wiring interrupts power flow to the controller. Regularly checking and fully charging the battery is crucial to ensure adequate power supply. Additionally, routine maintenance including battery health checks helps prevent unexpected power issues.

Overheating caused by excessive current through MOSFETs can trigger thermal shutdown, especially under heavy load or inadequate cooling, halting startup. Internal component damage, such as burnt MOSFETs or short circuits on the control board, disrupts signal processing and prevents powering on.

Additionally, blown fuses or tripped circuit breakers from overloads cut power to the controller. To restore function, inspect wiring integrity, verify fuse condition, ensure proper cooling, and consider replacing the controller or circuit board if internal faults persist. Understanding proper maintenance and component care can help avoid these failures.

Motor Faults That Prevent Powering On

If your e-scooter won’t power on, a motor fault could be triggering a safety shutdown controlled by the controller.

The controller monitors motor conditions and cuts power to prevent damage when it detects issues like overheating or electrical faults.

Understanding how these interactions cause startup failure helps pinpoint whether the motor or controller needs attention.

Performing a thorough visual inspection of the motor and its connections can often reveal signs of damage or wear that contribute to power issues. It is also important to test continuity and voltage of the motor wiring with a multimeter to detect electrical problems early.

Controller Malfunction Effects

When your e-scooter fails to power on, controller malfunctions often lie at the root of the issue, manifesting as motor faults that interrupt the electrical flow essential for startup. A faulty controller can cause no power output, continuous motor running, or intermittent power cycling.

You should inspect the controller box for physical damage such as cracks, burn marks, or melted wires. Use a multimeter to verify throttle and brake signals to pinpoint electrical faults. Recognizing error codes on the scooter’s display can also help diagnose controller issues. Additionally, checking the ignition wiring connections can reveal faults that prevent proper power delivery.

Key controller malfunction effects include:

- Short circuits causing total power loss

- Overheating from motor winding shorts

- Faulty MOSFETs locking power on

- Voltage regulation failures cutting motor power

- Intermittent motor response despite battery charge

Before beginning these checks, perform an initial inspection to ensure the scooter is off and not charging, and verify all connections and wiring are tight and intact.

Motor Safety Shutdown

Although your e-scooter may seem powered on, motor safety shutdowns can prevent it from actually starting by cutting power to protect internal components. These shutdowns activate when sensors detect overheating, mechanical faults like dislodged motor belts, or abnormal resistance from stuck wheels.

The battery management system (BMS) also plays a critical role by cutting power during overcharge, voltage irregularities, or cell imbalances. Electrical protections trigger shutdowns if fuses blow or circuit breakers trip due to overloads.

Additionally, safety interlocks linked to the brake system disable motor activation if the brake lever is engaged or misaligned. Faulty wiring, loose connectors, or internal motor debris further disrupt power flow causing shutdowns.

To resolve these issues, inspect connections, test battery voltage, reset the BMS, and check brake sensor alignment. Ensuring proper battery management and power delivery is essential to prevent unexpected motor shutdowns and maintain scooter performance.

Display and Indicator Malfunctions

You need to first check the display power indicators to confirm the scooter is receiving adequate voltage. Inspect the screen connections for loose or corroded plugs that can disrupt signal flow. Diagnosing display failures often involves testing continuity and verifying controller communication to isolate the malfunction.

In some cases, performing a firmware reset or updating the display software can resolve unresponsiveness caused by glitches. Additionally, regularly inspecting and maintaining key components like the folding lever and release buttons helps ensure overall scooter stability and function.

Display Power Indicators

Since the display power indicators provide critical feedback on your e-scooter’s battery status and system health, any malfunction can complicate diagnosing power issues. A blinking or absent battery indicator often signals battery or power delivery faults rather than display defects.

Despite a full charge, a blinking battery alert icon on the display may indicate a possible glitch or an issue with the battery connection. Regular maintenance of electrical connections helps ensure reliable indicator performance.

You should check for corrosion or loose battery terminals, as they can prevent accurate status readings. Additionally, faulty power switches or wiring faults might disrupt indicator functionality.

The Battery Management System may shut down output to protect the battery, causing erratic or no display.

To troubleshoot effectively, consider these points:

- Inspect battery voltage under load to confirm power presence

- Check battery terminals for corrosion or looseness

- Test power switch functionality and wiring integrity

- Verify fuse and circuit breaker status along the power path

- Observe indicator behavior for signs of BMS intervention and understand how power delivery issues can affect these signals.

Screen Connection Issues

Display power indicators often reveal underlying issues with battery connections or power delivery, but problems with the screen itself can also prevent your e-scooter from turning on. Constructing a stable base and ensuring secure wiring connections can improve overall device reliability.

Faulty wiring, such as damaged or loose cables connecting the display to the battery or controller, frequently causes screen malfunctions. Vibrations can loosen connectors, and moisture or dirt may corrode contacts, increasing resistance or causing shorts.

Defective power switches or display buttons can fail to send activation signals due to wear or oxidation, interrupting power delivery. Water ingress inside the display, even with imperfect sealing, damages internal circuits and wiring harnesses. In some cases, a faulty or blown fuse related to the display circuit may prevent the screen from powering on.

Additionally, controller faults can halt voltage to the screen, while blown or missing fuses dedicated to the display circuit cut off power entirely.

Regular inspection and secure connections are essential for proper screen function. Using durable, weather-resistant components can help prevent issues caused by environmental exposure.

Diagnosing Display Failures

When diagnosing display failures on your e-scooter, start by checking the power switch and key switch, as faults here commonly prevent the display and indicators from activating.

Next, inspect fuses and circuit breakers for continuity since blown fuses interrupt power flow.

Verify battery voltage at the controller connector to rule out low voltage or wiring issues. It is important to use a Battery State of Charge chart to interpret voltage readings accurately. Examine the speed controller’s internal electronics for faults affecting signal transmission.

Finally, check all non-screen display connectors for looseness, corrosion, or damage that can cause power disruptions.

Confirm that power and key switches fully engage. Test fuse integrity and secure fuse holders.

Measure battery voltage at controller terminals. Diagnose the speed controller for internal faults. Inspect and secure display wiring harnesses.

Effects of Corrosion and Moisture on Electrical Components

Although e-scooters are designed to endure everyday use, corrosion and moisture substantially impair their electrical components‘ performance. Rust forms when metal parts contact moisture and oxygen, creating iron oxide that insulates and weakens connections, increasing electrical resistance.

Corrosion and moisture degrade e-scooter electrical components by insulating connections and increasing resistance.

This corrosion disrupts signal and power transmission, causing malfunctions and intermittent power losses. Moisture intrusion can short circuit controllers, batteries, and motors, reducing battery efficiency and causing erratic motor responses. To combat these issues, selecting models with IP54 or higher waterproof ratings helps protect vulnerable components.

Inside the motor, rust degrades windings and bearings, lowering efficiency and lifespan due to overheating and mechanical wear. Corroded moving parts may seize, halting mechanical operation.

Additionally, rust on iron-based frames decreases grounding efficiency. To maintain ideal function, you must prevent moisture exposure and corrosion, as these factors critically undermine the scooter’s electrical integrity and overall reliability.

How to Test and Revive a Dead Battery?

Start by measuring the battery voltage with a digital multimeter and compare it to the nominal voltage to assess its charge level.

If the battery reads low, perform a deep charging process using the manufacturer-recommended charger to restore capacity.

Proper charging ensures accurate load test results; testing uncharged batteries can lead to false negatives, so batteries should be fully charged before testing proper charging.

Monitor for signs like rapid voltage drop or failure to hold charge, which indicate the battery may need replacement.

Checking Battery Voltage

Since a dead or weak battery is a common cause of an e-scooter not turning on, accurately testing its voltage is essential. Use a digital multimeter set to DC voltage mode, ensuring the battery is off and disconnected before measuring. Connect the red probe to the positive terminal and the black to the negative terminal. When using the multimeter, take care to avoid short-circuiting the battery terminals as this can cause damage or injury.

A fully charged 48V battery reads between 48.0V and 54.6V; readings below 40V suggest discharge or damage. To revive or confirm battery health:

- Measure voltage to determine charge state

- Charge if voltage is low, then monitor increase

- Perform load testing to detect voltage drops

- Avoid deep discharging to prevent damage

- Store batteries cool and dry, checking voltage regularly

Deep Charging Process

When your e-scooter’s lithium-ion battery enters protection mode due to deep discharge, you’ll need to perform a controlled deep charging process to revive it. Start by “jump starting” the battery with brief, controlled voltage from a compatible charger to reactivate the battery management system. It is important to use the manufacturer-provided charger or a compatible one to avoid damaging the battery during this process.

Disconnect all power sources for 10-15 minutes to reset internal electronics, and inspect charging ports for corrosion or debris that could block communication.

Use a multimeter to monitor voltage increases during intermittent charging sessions, ensuring the battery doesn’t overheat. Keep the battery in a cool, ventilated area and avoid overcharging.

After recovery, confirm the scooter powers on and operates normally. This precise procedure helps restore functionality without causing further battery damage.

Signs Battery Needs Replacement

How can you tell if your e-scooter’s battery is failing and needs replacement? Key indicators include reduced range despite full charges, slower top speeds, and intermittent power issues. Physical damage like swelling or corrosion also signals battery failure.

To test battery health, measure voltage output and monitor discharge rates. A rapid drain or low voltage confirms degradation. You can attempt revival by performing full charge-discharge cycles and ensuring clean, secure connections. It is important to purchase high-quality batteries to ensure safety and performance when replacing the battery.

However, if the battery shows physical damage or consistently underperforms, replacement is necessary.

Look for these signs:

- Noticeable range reduction and frequent charging

- Swollen or deformed battery casing

- Low voltage output or rapid discharge

- Battery warning indicators on the display

- Physical damage or overheating during use

Frequently Asked Questions

Can Extreme Temperatures Cause My E-Scooter Not to Turn On?

Yes, extreme temperatures can prevent your e-scooter from turning on. In cold weather, your battery’s chemical reactions slow down, reducing voltage output and causing startup failures.

In high heat, protective mechanisms may shut down the motor to avoid damage. To guarantee reliable operation, keep your scooter within the manufacturer’s recommended temperature range, avoid prolonged exposure to freezing or overheating, and allow the battery to acclimate before use in extreme conditions.

Does Firmware Affect the Scooter’s Ability to Power On?

Yes, firmware directly affects your scooter’s ability to power on. It manages power control and motor functions, so corrupted or outdated firmware can prevent startup or cause unresponsive power buttons.

You should check for updates via the app or manufacturer’s site and perform a hard reset by disconnecting the battery to clear glitches.

Regular firmware maintenance improves reliability and prevents power-related failures in your scooter’s operation.

Could a Software Glitch Prevent Startup Even With a Good Battery?

Yes, a software glitch can prevent startup even if your battery is fully charged. Corrupted firmware or failed updates may disrupt the power-on sequence, causing the scooter not to turn on.

You should try a factory reset by disconnecting and reconnecting the battery or controller. If that doesn’t work, you’ll likely need professional support to re-flash the software or address deeper system issues.

Are There User-Reset Options if the Scooter Fails to Start?

Yes, you can reset your e-scooter yourself if it won’t start. First, disconnect the charger and press the circuit breaker reset button if available.

Check that the battery is fully charged and properly connected. Sometimes unplugging and replugging the battery helps.

Also, verify safety switches like the kickstand and brake sensors are correctly positioned.

Finally, reseat controller wiring to reset communication errors. These steps often restore power without professional help.

Can Aftermarket Parts Cause Compatibility Issues Leading to No Power?

Yes, aftermarket parts can cause compatibility issues that prevent your e-scooter from powering on. If the controller’s voltage, amperage, or communication protocols don’t match the original, power delivery can fail.

Incorrect motor-controller pairing, incompatible battery management systems, or improper wiring can trigger automatic cutoffs or shorts. These mismatches disrupt electrical feedback, cause erratic behavior, or trip fuses, resulting in no power to your scooter’s system.

Restore Your E-Scooter Power

Think of your e-scooter as a complex circuit maze where every connection, like a pathway, must be clear for power to flow. If it won’t turn on, one wrong turn—a dead battery, faulty wiring, or a stuck safety switch—can block the current.

By systematically checking each component, you restore the flow and bring your scooter back to life. When in doubt, don’t hesitate to consult a professional to navigate this electrical labyrinth safely.